Not Your Dad’s Manufacturing

Originally Published: 2 October, 2013

Over the summer we had a summer camp for 7th and 8th graders. The idea was to see if we could get younger kids excited about the technology of manufacturing so when they are making choices later in life they might consider training and careers in manufacturing.

I wrote an article about it for the experience Next Generation Manufacturer News Letter

The camp by all accounts was a big hit and we are hoping to do a series of these kind of camps next summer.

Can you imagine a world where you ask Susie what she wants to be when she grows up and instead of ballerina or brain surgeon she says “I want to be a CNC programmer.”? Amazingly enough I can, but it won’t happen by itself, we have to do something to make it happen.

The media and the pundits talk about outsourcing and unemployment and frequently even blame these trends on the “skills gap” in manufacturing. For years I’ve been hearing about and even talking about the skills gap myself. I really couldn’t say how many times I’ve heard company owners or managers say something like “I would buy another machine if I could find someone to run it.”

The solution seems obvious, train more people to run them. And I’ve always known that the true long-term solution was to get young people excited about the technology and possibilities so that when they grow up just a little bit they can pursue training in and then a career in manufacturing.

It’s one thing to know the solution, quite another sometimes to implement it. Several weeks ago I got the opportunity to put my money where my mouth was and see if I could train 16 seventh and eighth graders to operate CNC machine tools, to make something, and to get them excited about the technology.

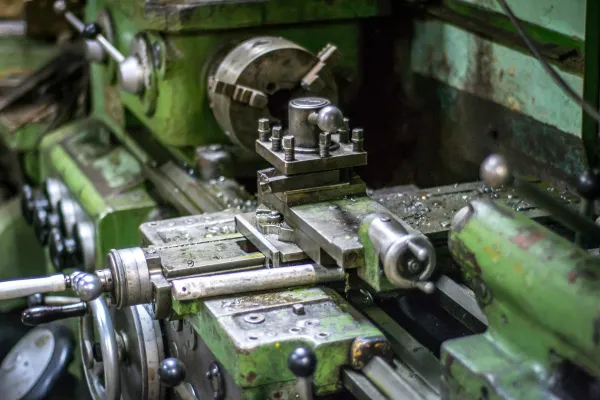

I work at Worcester Polytechnic Institute, WPI. We are a four-year research university with what might be the best facility in the world for educating engineers about CNC machining. The school runs many summer camps every year and many of those camps like to take a tour of our lab for an hour or so one afternoon during the week of their stay. When we have enough advance notice and enough time with the students will set up a demo or even allow them to operate the machines a little bit to make something that they can bring home, them trying to get some excitement generated.

For years we have done towards and demos for hundreds of students attending summer camps and WPI. These camps are focused on topics like science and technology, engineering technology, computer-aided design, music technology, robotics, and even crime scene science. One day at the end of an unrelated committee meeting I was speaking with the director of the summer programs office and I suggested it would be great if we did a summer camp that focused on CNC machining and manufacturing technology. Well that was all it took I was signed up and committed.

Our plan was simple we would scale back the instructions and tasks we give the WPI freshman lab, prepare several steps in advance, and see how it went. By the end of the day on Monday we’d finish all of the scheduled activities for Tuesday and shifted gears. The instructions didn’t need to be scaled back, the 12-year-olds were just as capable as the 18 and 19-year-old the WPI freshman. By the end of the week they all used a laser cutter to engrave a design of their own on an aluminum part we had given them and were all able to use CAM software to program simple tool paths for both mills and lathes. At the same time they learned how to operate and perform basic set up operations on CNC mills and lathes.

They all made several chess pieces and components for Stirling engine which they assembled and ran on the last day of camp. On that last day we held a reception and tors for the parents and since we spent all week thinking up new exercises and activities (we finish the original scheduled activity on Wednesday sometime) we didn’t really have a plan for the reception. We told the kids to show the lab to their parents and within a few minutes you could hear spindle starting they were just getting towards their parents they were running the machines and showing what they could do.